Quality Systems & Processes

We’ve set the standard for quality in the industry through our leadership role within the Wiring Harness Manufacturer’s Association (WHMA), and IPC/WHMA A-620 certification.

ISO 9001:2015

Poka-Yoke Fixturing

IPC/WHMA A-620 (C)

At ALTEX, our quality control systems and processes are continually reviewed at all stages of the cable assembly and wire harness manufacturing process to ensure accuracy and promote continuous improvement. In addition to quality assurance processes such as optical inspection, electrical verification, in-circuit tests, and probe and pull force testing, we validate all of our equipment to guarantee strict adherence to industry certifications and compliances.

If you’re considering our services, we encourage you to inquire about our quality audits. We comply with our customers’ specified quality standards and proudly provide our customers with complete transparency into the manufacturing process.

POKA-YOKE FIXTURING

A key part of our manufacturing best practices is poka-yoke fixturing, also known as “mistake-proofing.”

Our custom wire harness boards with light-guided assembly aids guarantee processes are done right the first time; eliminating costly rework and other reactionary methods of defect detection common in traditional testing methods.

Fixturing ensures:

- Products are consistent and free of defects

- Improved efficiency and safety

- Faster production, cycle times and lead times

- Highest possible quality

- Lower overall cost

Check out our solution brief to find out how we utilize poka-yoke fixturing to prevent the most common (and costly) manufacturing errors.

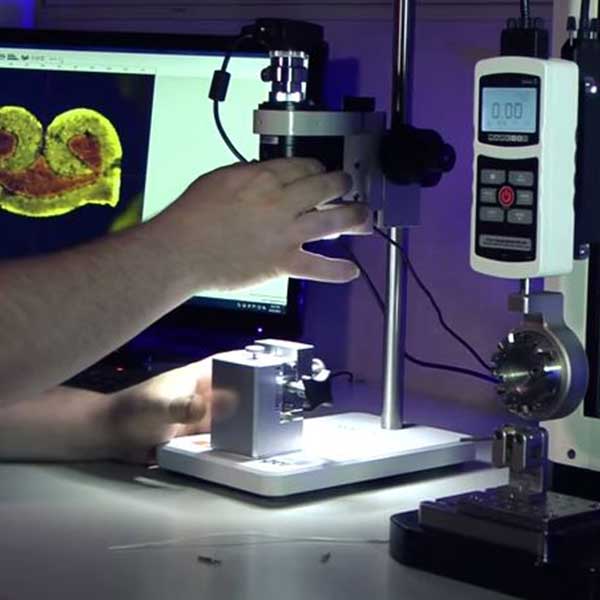

CRIMP QUALITY ASSURANCE

Assuring crimp quality is one of the most important insurance policies against product defects. No matter how well you’ve built everything else, wire harness quality depends upon crimp integrity.

Our thorough analysis consists of inspecting high quality cross-sectional images and functional testing.

Equipment includes:

- Schleuniger’s MicroGraph System – Cross Sectioning

- Programmable Pull Force Tester

CERTIFICATIONS

Strategic relationships and attention to quality are the keys our success. We’re committed to the highest standards in everything we do for our customers from initial discussions through engineering and production.

WESTFIELD, INDIANA CERTIFICATIONS

ISO 9001:2015

IPC/WHMA A-620 (C)

Production Part Approval Process (PPAP)

Automotive Industry Action Group (AIAG) Guidelines

Environmental Compliance

Partnered with RSJ Technical Consulting

RoHS Compliance

NOGALES, MEXICO CERTIFICATIONS

ISO 9001:2015

UL Registration

IPC/WHMA A-620 (C)

PARTNERSHIPS

ALTEX is a member of the Indiana Chamber of Commerce and Wellness Council of Indiana; as well as registered with the Purdue Manufacturing Extension Partnership’s Made in Indiana program which highlights the contributions manufacturing makes to the state’s economy.

We’re leading the industry in setting quality standards.

We’re helping to set and continually update the standards for quality in the cable and wire harness fabrication and installation industry with our leadership roles within the Wiring Harness Manufacturer’s Association and IPC.

Ready to start a new project? Let's work together >